Burnout (article from Wearables Magazine)

- Posted by mwinner

- On November 20, 2015

- 0 Comments

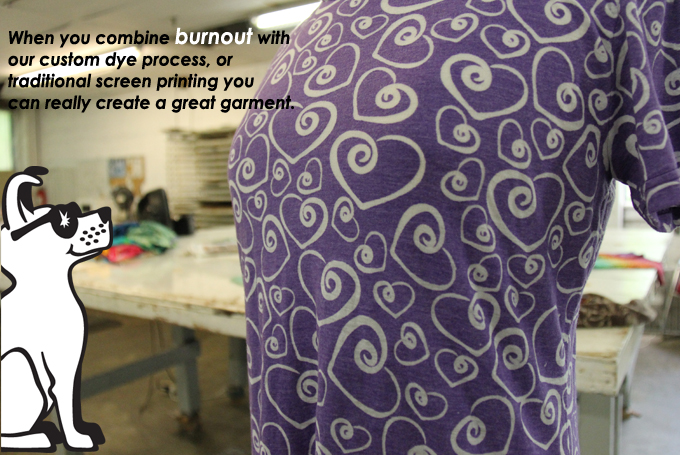

When it comes to T-shirts, Sundog Productions tries to stay one step ahead of the game. As the burnout look continues to make a splash in the fashion T-shirt world, finding ways to make your burnout a standout is no easy task. That’s where Sundog comes in with its custom burnout T-shirt patterns.

Traditional burnout tees are made from rolls of uniform burnout fabric with a random splotchy design that’s set before they leave the factory. But Sundog’s new process removes the random, allowing employees to give poly/cotton blends a unique burnout design.

“We create artwork in the same way we would for screen printing a one-color print,” says John Sague, director of sales, “and then we apply our burnout formula to the shirt using screen-printing equipment.” After the formula has been applied, the garment is cured in a dryer, completing the process. Sundog’s new method means that companies can order a fashionable tee with their logo burned directly into the fabric rather than merely printed on premade burnout material.

But Sundog’s innovations don’t stop there.

“Our newest thing is that we can actually color the burnout portion of the tee as well,” Sague says, adding that the market for it is already brimming. “We recently did a navy blue tee and colored the burnout portion orange for the University of Virginia.” Two-tone burnout designs may appeal to schools with fashion-forward students, or to sports fans who want to show spirit in style.

Sague also sees the new technique as beneficial for the industry as a whole. By burning out and mass-producing tees with generic designs like peace signs, hearts or music notes, Sundog will be able to offer various organizations a fashionable themed tee that they can screen print with their name or logo. “Whatever the customer is looking for,” he says, “we can now pretty much do it.”

And Sundog is more than a one-trick puppy. The decorator also has developed Sea-Ink, where it substitutes a seaweed-based substance that molecularly bonds to the fabric for the glue normally found in dyes. The resulting screen-printed garments won’t feel tacky to the touch or fade with washing. Says Sague, “We’re always looking to try new things.”

– Haley Miller (Wearables Magazine)